The bracket is a structural element that connects the pipes of the floating cage. The strength of the bracket is essential for the functionality of the cage

Molded Brackets

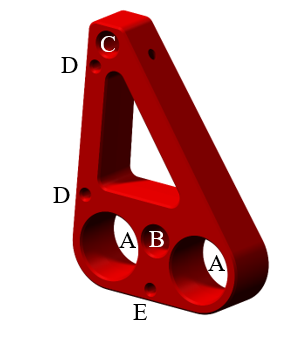

The design of the brackets may include two or three locations for the floating pipes (A) and possibly an additional location for the walkway pipe (B). In the upper part of the upright, there is a location where is placed the HDPE pipe which acts as a handrail (C). The brackets can be equipped with attachment points specifically designed for anchoring the net and the sinkers (D) using cables or ropes. Furthermore, inside the brackets can be made a place in order to connect it to the sinking system. The same application can be used to place a safety chain that prevents damages of the floating ring in the installations most exposed to strong waves. SYSTEM GROUP MARINE can provide a wide choice of brackets designed according to the customer’s specifications, engineered by the R&D department according to the characteristics of the site and the strength required for the cage.

Formed Brackets

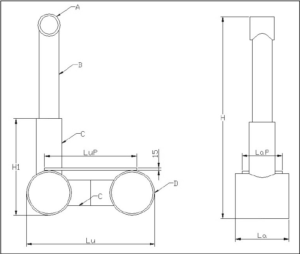

Formed brackets are made by butt-welding (UNI 10520) of PEAD pipes with varying OD, from 140mm to 280mm and welding with portable extruder of PEAD sheets according to prEN13476-1. The technicians are licensed according to DVS 2212-2.

| Model | PF250 | |

| H | mm | 1250 |

| H1 | mm | 600 |

| Lu | mm | 795 |

| La | mm | 330 |

| LuP | mm | 570 |

| LaP | mm | 250 |

| A | Pipe PE 100 DN140 SDR 11 (th. 12.6 mm) | |

| B | Pipe PE 100 DN125 SDR 11 (th. 11.4 mm) | |

| C | Pipe PE 100 DN160 SDR 11 (th. 14.6 mm) | |

| D | Pipe PE 100 DN280 SDR 26 (th. 10.7 mm) | |

| Tolleranze | mm | +/- 10 |